Cylinder Liners in Engines: Essential Components for Optimal Performance

The cylinder liner in engine design plays a pivotal role in the overall performance and longevity of a diesel engine. As diesel engines continue to be the backbone of numerous industries, understanding the intricacies of their components, especially cylinder liners, is paramount for engineers, mechanics, and spare parts suppliers alike.

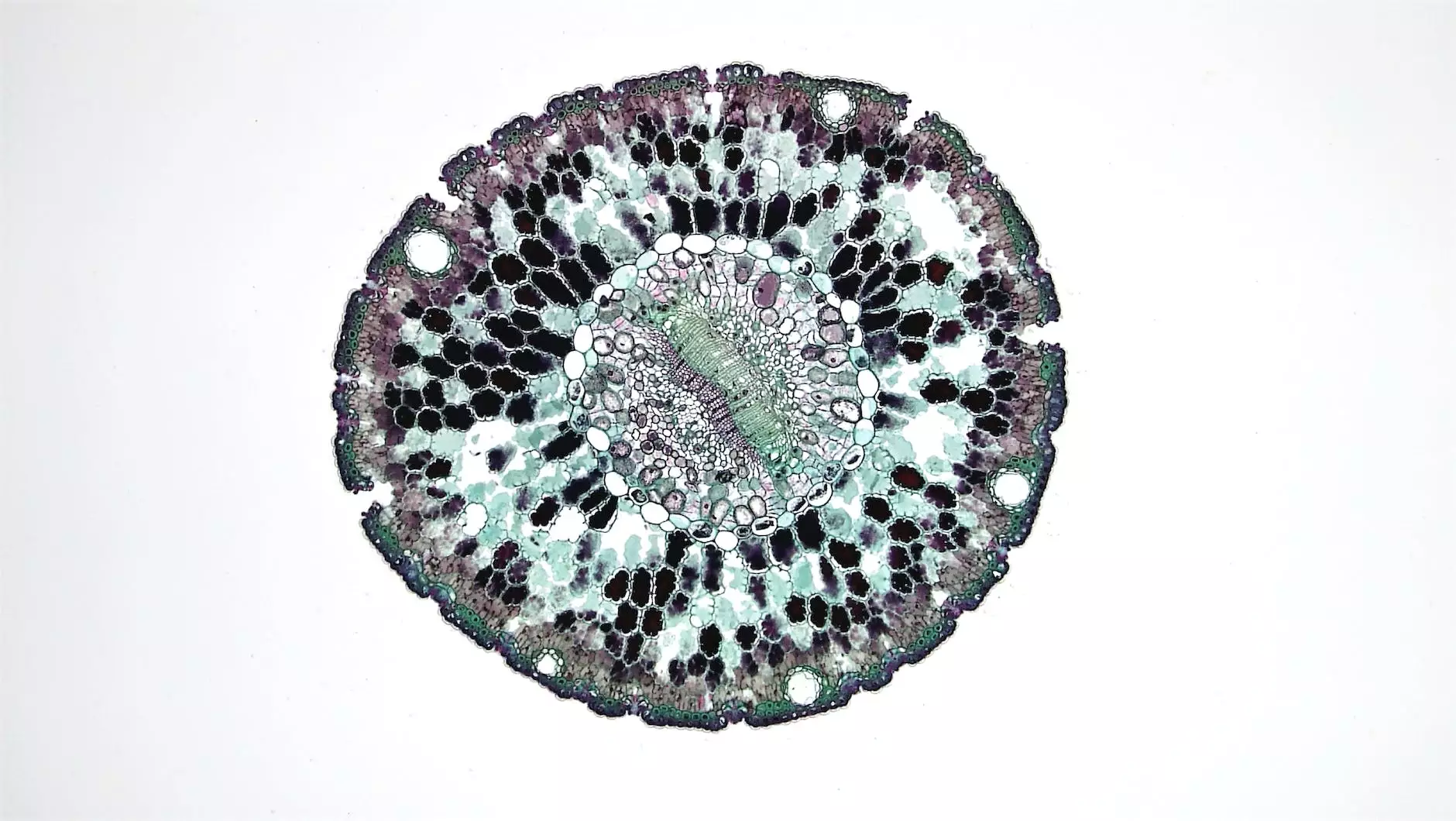

Understanding Cylinder Liners

Cylinder liners, also known as cylinder sleeves, are precision-engineered components that line the cylinders of an engine. They form the interface between the engine block and the combustion chamber, hosting the piston and facilitating the combustion process. These liners are critical because they:

- Reduce Friction: They offer a smooth surface for the piston, reducing wear and tear.

- Maintain Cylinder Integrity: They prevent the deformation of the cylinder walls under high pressures.

- Enhance Cooling: They help in dissipating heat away from the combustion chamber.

- Facilitate Engine Repair: They provide a means to restore engine cylinders to their original dimensions after wear.

Types of Cylinder Liners

Cylinder liners can be categorized into two main types based on their design and applications:

1. Dry Cylinder Liners

Dry cylinder liners are installed directly into the engine block without any coolant flowing between them. This design is typically lighter and allows for easier replacement. They are commonly found in smaller diesel engines and offer various advantages:

- Less complex installation: They simplify the manufacturing process and reduce costs.

- Better sealing: The direct contact with the engine block provides optimal sealing, reducing the risk of leaks.

2. Wet Cylinder Liners

Wet cylinder liners, on the other hand, are surrounded by coolant, which helps in better heat dissipation. They are usually used in larger, heavy-duty diesel engines:

- Enhanced cooling: The moist environment helps to quickly transfer heat away from the combustion area.

- Extended lifespan: They tend to have a longer service life due to better thermal management.

- Ease of replacement: When a liner wears out, it can be replaced without replacing the entire block.

Factors Affecting Cylinder Liner Performance

Several factors influence the performance and longevity of a cylinder liner in engine designs:

1. Material Composition

Traditionally, cylinder liners were made from cast iron, but advancements in technology have introduced various alloys and composite materials that enhance durability and performance.

- Cast Iron: Provides excellent wear resistance and is the most common material used.

- Steel: Offers high tensile strength and is suitable for high-performance engines.

- Aluminum Alloys: Lightweight and corrosion-resistant, ideal for modern engines.

2. Manufacturing Precision

Precision in manufacturing is crucial. Cylinder liners must meet strict tolerances to ensure a perfect fit within the engine block. Any deviations can lead to high wear rates and thermal inefficiencies.

3. Surface Treatments

Surface treatments like nitriding and chrome plating can significantly enhance the wear resistance of cylinder liners. These treatments create a hard surface that can better withstand the stresses of operation.

The Role of Cylinder Liners in Engine Performance

The performance of a diesel engine is heavily dependent on the efficiency of its parts, and cylinder liners play a leading role in this respect. Here are some ways they impact the overall performance:

1. Compression Ratio

Cylinder liners greatly influence the engine's compression ratio, which is vital for achieving optimal combustion efficiency. A correct compression ratio maximizes power output while minimizing fuel consumption.

2. Emission Control

As environmental regulations tighten, manufacturers design cylinder liners to help reduce emissions. Properly fitted liners can help in lowering unwanted gases produced during combustion.

3. Noise Reduction

Engine noise can be decreased significantly with the use of high-quality cylinder liners. Their design and materials contribute to a smoother operation, leading to quieter engines.

Maintenance and Inspection of Cylinder Liners

For engine health, regular maintenance and inspection of cylinder liners are essential. Here are some maintenance tips:

- Routine Inspections: Regular checks can identify any early signs of wear or damage.

- Proper Lubrication: Ensuring that adequate lubrication is maintained will protect and prolong the life of the cylinder liners.

- Cooling System Maintenance: For wet liners, maintaining the coolant system is crucial to prevent overheating.

Conclusion: The Future of Cylinder Liners

As the demand for more efficient and powerful engines rises, the role of the cylinder liner in engine technology will continue to evolve. Innovative designs and materials are expected to emerge, driving improvements in performance, durability, and compliance with emissions standards.

For *spare parts suppliers*, understanding these advancements and the importance of cylinder liners will aid in providing customers with the best products available. By staying informed on the latest trends and technologies regarding cylinder liners, businesses like client-diesel.com can position themselves at the forefront of diesel engine parts supply.

Additional Resources

If you're looking to purchase cylinder liners or need more information about diesel engine parts, consider visiting client-diesel.com for a comprehensive selection and expert advice.